The solver of the large column distance problem:

With the continuous improvement of the owner’s requirements for space utilization, to meet the production needs of various industries, the column spacing has been expanded from the previous 6~9m to the current 12m and above. For the column spacing of 12m and above, ordinary purlins can no longer meet the requirements. , The truss-type purlin can easily solve the problem and solve the problem for the owner.

GB51022-2015 [Technical Specification for Steel Structures for Lightweight Portal Framed Buildings] Chapter 9, Purlin and Wall Beam Design 9.1.1 clearly states that "truss-type components should be used for simply supported purlins with a span greater than 9m".

Customized service:

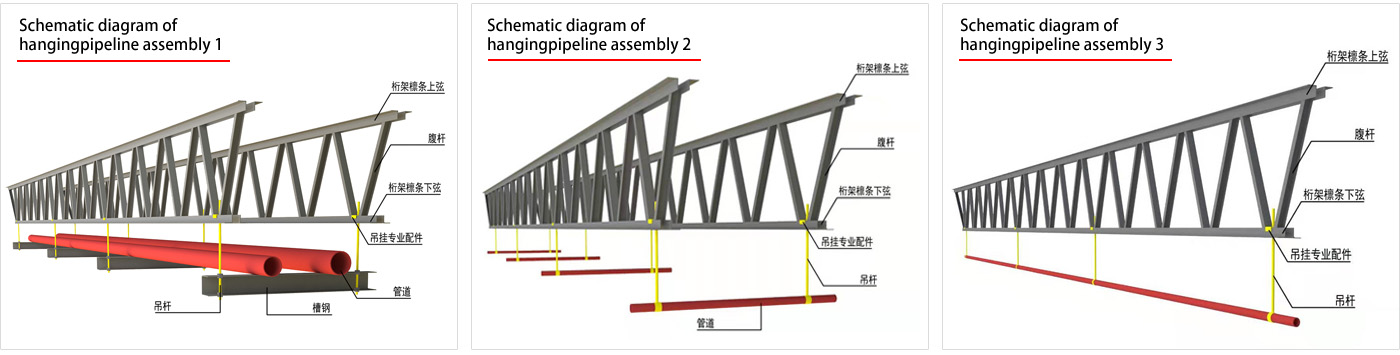

Truss-type purlins can be customized according to the height, span, load-bearing capacity and customer needs. RK series steel trusses have up to 96 models in the standard load table for customers to choose from, but not limited to this; truss-type purlins allow pipes , Bridge, and electrical pipes pass through the structure.

Advanced hanging system:

Due to the special structure of the Peterson truss with an advanced hanging system, the hanging problem can be easily realized without welding or drilling. And in the early stage of the design, you can reserve the position in advance, and the hanging position can be moved at will, saving the amount of renovation.

Save total project cost:

Peterson steel trusses can save the total project cost by saving steel consumption and advanced hanging system. At the same time, the company continues to study new truss connection modes, so as to reduce costs and improve product core competitiveness. The owner can choose different connection methods for use according to their needs.

Replacement of C/Z Purlin:

|

Comparison table of technical and economic analysis of steel truss purlins and cold-formed thin-walled Z purlins - general working conditions |

||||

|

Steel truss purlin |

Z-shaped purlin |

Steel truss purlin |

Z-shaped purlin |

|

|

Bay Spacing |

12m |

|||

|

Spacing |

1500mm |

1500mm |

1500mm |

1500mm |

|

Bay Spacing |

PSJ-R500K01 |

XZ300*80*25*2.3/3.0 |

PSJ-R600K02 |

XZ300*85*25*2.8/3.3 |

|

Material |

Q420 |

Q345B |

Q420 |

Q345B |

|

Normal load |

Dead load:0.2KN/㎡;Live

load:0.5KN/㎡;Wind load:0.3KN/㎡; |

Dead load:0.2KN/㎡;Live load:0.5KN/㎡;Wind load:0.35KN/㎡; |

||

|

Steel consumption for linear meters |

8.366kg/m |

10.373kg/m |

9.63kg/m |

13.048kg/m |

|

Steel consumption per square meter |

5.577kg/m*m |

6.915kg/m*m |

6.42kg/m*m |

8.699kg/m*m |

|

Conclusion |

For the roof system with 12m column

spacing,

under the same load requirements,

the use of Peterson purlins can

save up to 19% of the steel

consumption than the cold-formed thin-walled C.Z

purlins.

|

For a roof system

with a column spacing of 12m, |

||

|

Comparison of technical and economic analysis of steel truss purlins and cold-formed thin-walled Z purlins - main line conditions |

||||

|

Steel truss purlin |

Z-shaped purlin |

Steel truss purlin |

Z-shaped purlin |

|

|

Bay Spacing |

12m |

|||

|

Spacing |

1500mm |

1500mm |

1500mm |

1500mm |

|

Bay Spacing |

PSJ-R500K02 |

(2)XZ300*80*25*2.0/2.3 |

PSJ-R600K03 |

(2)XZ300*85*25*2.3/2.8 |

|

Material |

Q420 |

Q345B |

Q420 |

Q345B |

|

Load requirements |

Dead load:0.2KN/㎡;Live

load:0.5KN/㎡;Wind load:0.3KN/㎡; |

Dead load:0.2KN/㎡;Live load:0.5KN/㎡;Wind load:0.35KN/㎡; |

||

|

Special load |

Main line load:180kg/m |

Main line load:240kg/m |

||

|

Steel consumption for linear meters |

9.26kg/m |

17.742kg/m |

10.62kg/m |

21.826kg/m |

|

Steel consumption per square meter |

6.173kg/m*m |

11.828kg/m*m |

7.08kg/m*m |

14.551kg/m*m |

|

Conclusion |

For main line hanging, the special

suspension system

of Peterson steel truss purlin can save 48% of steel.

And

in the installation of mechanical and electrical

equipment in the process of

eliminating the traditional

installation process of the necessary air welding

and drilling.

|

For main line hanging, Z-purlins must be

suspended by 4 purlins,

and special suspension system of Peterson steel truss

purlins is used.

Only 2 purlins are suspended, saving 51% of steel.

And in

the installation of mechanical and electrical

equipment in the process of

eliminating the traditional

installation process of the necessary air welding

and drilling.

|

||

Replacement Of High Frequency Welding Purlin:

|

Technical and economic analysis comparison table of steel truss purlin and |

||||

|

Steel truss purlin |

High frequency welding H-shaped rigid purlin |

Steel truss purlin |

High frequency welding H-shaped rigid purlin |

|

|

Column distance |

12m |

15m |

||

|

Spacing |

1500mm |

1500mm |

1500mm |

1500mm |

|

Section size |

PSJ-R500K01 |

H350*150*3.2*4.5 |

PSJ-R650K02 |

H350*150*4.5*6 |

|

Material |

Q420 |

Q345 |

Q420 |

Q345 |

|

Load |

Dead load: 0.2KN/㎡; Live load: 0.5KN/㎡; Wind load: 0.45KN/㎡; Snow load: 0.45KN/㎡;Suspension load: 0.3KN/㎡ |

|||

|

Steel consumption for linear meters |

8.366kg/m |

17.91kg/m |

9.82kg/m |

24.3kg/m |

|

Steel consumption per square meter |

5.577kg/m*m |

11.94kg/m*m |

6.547kg/m*m |

16.2kg/m*m |

|

Expanded area (m*m) |

11.3 |

15.6 |

14.6 |

19.5 |

|

In conclusion |

For the roof system with 12m column spacing,

The use of Peterson steel truss purlins saves up to 53% |

For the roof system with 15m column spacing,

The use of Peterson steel truss purlins saves up to 60% of the |

||

|

It can be seen from the above data that under the same load, the higher the column spacing requirement,

At the same time, it can save more than 25% of the fireproof coating area and more Because the Peterson hollow steel truss purlin system has a special suspension system, it saves the air welding and drilling necessary for traditional installation during the electromechanical equipment installation process, thereby saving more than 30% of the labor cost of the electromechanical contractor. |

||||